VARIABLE PRESSURE FOAMING VPF

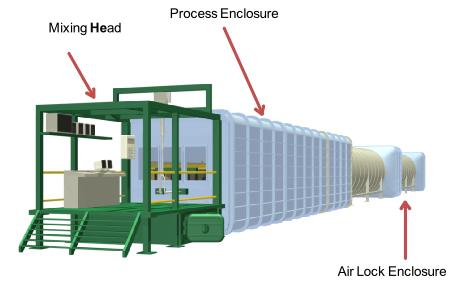

The VPF™ (variable pressure foaming) process is based on the continuous foaming in an airtight enclosure, where flexible foams are produced under controlled atmospheric conditions of under or overpressure.

The VPF™ process requires no auxiliary blowing agents, such as Methylene Chloride, Acetone etc these blowing agents are replaced by the effects of vacuum.

The foaming gases given off during the VPF™ process, are very small in volume and can be filtered through an activated carbon filter which makes the process completely clean, exceeding the most stringent environmental regulations by far.

VPF Capabilities

VPF Capabilities

Continuous Slabstock Machines

Foam Machine Components

Flat Top Systems

Mentor Computer Control Systems

Tank Farms, Pipework and Temeprature Control

Specialist Foaming Machines

Rigid Foam Equipment